Axle Load Assist for Commercial Vehicles

In the modern commercial transportation industry, maintaining vehicle efficiency while ensuring safety and regulatory compliance is a top priority. One critical component that ensures both these aspects is Axle Load Assist. This innovative technology helps operators of commercial vehicles manage and distribute loads effectively across all axles, thereby optimizing payload, improving vehicle handling, and ensuring legal compliance. In this comprehensive article, we delve into the importance of Axle Load Assist, its functionality, the benefits it offers to fleet operators, and how it can dramatically reduce wear and tear while increasing operational efficiency.

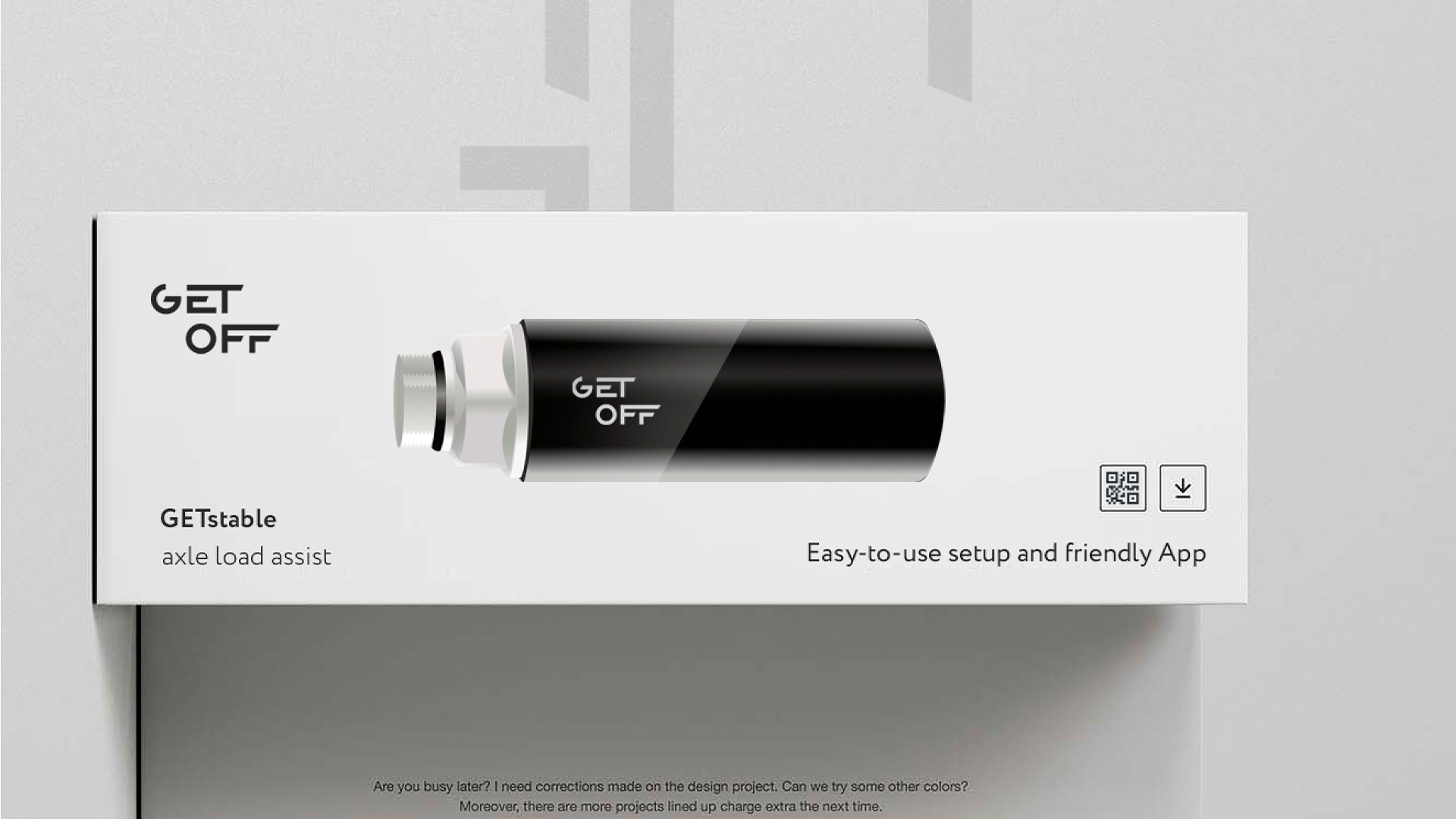

What is Axle Load Assist?

Axle Load Assist is a technology integrated into modern commercial vehicles, specifically designed to optimize the load distribution across a vehicle’s axles. This system monitors the weight on each axle in real time and adjusts the vehicle’s suspension to redistribute excess weight. As commercial vehicles frequently carry heavy and variable loads, improper weight distribution can lead to several challenges, including increased fuel consumption, premature tire wear, and compromised vehicle stability.

With Axle Load Assist, the vehicle’s onboard sensors and control systems automatically monitor and maintain the ideal axle load, helping to ensure safe and efficient operation. This functionality is particularly critical for vehicles with multiple axles, such as semi-trailers, buses, and heavy-duty trucks, where imbalanced loads can create significant operational issues.

How Does Axle Load Assist Work?

Axle Load Assist uses a combination of pressure sensors, air suspension systems, and load distribution algorithms to ensure that weight is evenly distributed. The process begins when the onboard sensors measure the load on each axle. These sensors are typically embedded in the suspension system or attached to the vehicle’s chassis. As the vehicle moves, the sensors provide real-time data, enabling the system to detect any imbalance in the load.

When a load imbalance is detected, the air suspension system makes precise adjustments to distribute the weight more evenly. By increasing or decreasing the air pressure in the suspension, Axle Load Assist helps to correct the load distribution. This balancing process occurs automatically, even during transit, ensuring that the vehicle operates within legal axle weight limits and maintains optimal performance.

The ability to make continuous adjustments is a major advantage, particularly for long-haul vehicles or those operating in varying terrains and conditions. The system is also designed to improve fuel efficiency by minimizing unnecessary drag caused by improper load distribution.

Key Benefits of Axle Load Assist

Axle Load Assist offers numerous benefits to fleet managers, drivers, and vehicle owners, ranging from operational efficiency to safety and compliance. Here are some of the key advantages:

1. Improved Vehicle Stability and Handling

Uneven axle loads can make a vehicle more difficult to control, especially at higher speeds or when navigating sharp turns. Axle Load Assist helps to enhance vehicle stability by maintaining an even load distribution, reducing the risk of swerving, rolling, or tipping over. This is particularly important for heavy-duty trucks and trailers, where load imbalances can easily lead to dangerous driving conditions.

2. Extended Tire and Suspension Lifespan

Excessive load on a single axle puts undue strain on the vehicle’s tires and suspension. Over time, this can lead to premature wear and increase the frequency of maintenance or part replacements. Axle Load Assist helps to evenly distribute weight, thereby reducing the wear on both the tires and the suspension system. By extending the lifespan of these components, fleet operators can significantly reduce maintenance costs.

3. Legal Compliance

In most countries, strict laws regulate the maximum allowable weight on each axle. Overloaded axles can result in costly fines and even vehicle impoundment. Axle Load Assist ensures that vehicles remain compliant with these legal limits by automatically adjusting the load distribution across all axles. This reduces the risk of non-compliance and the associated penalties.

4. Enhanced Fuel Efficiency

Proper weight distribution minimizes rolling resistance and aerodynamic drag, both of which contribute to increased fuel consumption. By maintaining optimal load distribution, Axle Load Assist helps to improve a vehicle’s overall fuel efficiency, which is a significant advantage for fleet operators looking to minimize operational costs. In an industry where fuel expenses can account for a large portion of operational budgets, even small improvements in fuel efficiency can translate to substantial savings.

5. Increased Payload Capacity

Axle Load Assist enables vehicles to carry larger payloads without compromising safety or stability. By distributing the weight evenly across all axles, the system allows operators to maximize their payload capacity while staying within legal limits. This means fewer trips are needed to transport the same amount of cargo, which directly increases operational efficiency and reduces fuel consumption.

The Role of Axle Load Assist in Fleet Management

For fleet operators, Axle Load Assist provides a practical solution to several common challenges. When integrated into fleet management systems, this technology can be used to monitor vehicle performance, optimize routes, and even predict maintenance needs based on load patterns. The system’s ability to provide real-time data also offers valuable insights that can help fleet managers make data-driven decisions.

Additionally, with the growing emphasis on sustainability and reducing carbon emissions, Axle Load Assist plays a vital role in helping fleets meet environmental regulations. By optimizing fuel efficiency and reducing wear and tear, this system contributes to lower greenhouse gas emissions and a smaller overall environmental footprint.

Axle Load Assist and Driver Safety

Driver safety is always a top priority, and Axle Load Assist contributes directly to safer driving conditions. Imbalanced loads can lead to unpredictable vehicle behavior, particularly in poor weather conditions or on uneven roads. The technology ensures that drivers have better control over their vehicles, reducing the likelihood of accidents caused by load shifts.

Furthermore, Axle Load Assist allows drivers to focus on the road without the added concern of constantly checking load distribution. This can lead to reduced driver fatigue, as the system automatically adjusts the load in real-time, providing a smoother and more predictable driving experience.

Future Developments in Axle Load Technology

As autonomous vehicles and smart transportation systems become more prevalent, the role of Axle Load Assist is expected to evolve further. Manufacturers are exploring ways to integrate AI and machine learning into load management systems, allowing for even more precise and predictive load distribution. These advancements will likely result in even greater safety and efficiency for commercial vehicles in the coming years.

Moreover, the increasing demand for electric commercial vehicles is driving the need for more efficient load management systems, as electric powertrains can be more sensitive to weight distribution than traditional internal combustion engines. In this context, Axle Load Assist will continue to play a critical role in ensuring that electric vehicles can operate safely and efficiently.

Conclusion

In the ever-evolving landscape of commercial transportation, Axle Load Assist stands out as a key technology that optimizes load distribution, enhances vehicle safety, and ensures compliance with regulatory standards. Its ability to improve fuel efficiency, reduce wear and tear, and extend the lifespan of critical vehicle components makes it an invaluable asset for any fleet operation. As we move towards more advanced vehicle technologies, including electric and autonomous vehicles, the role of Axle Load Assist will become even more crucial in maintaining the highest standards of performance, safety, and efficiency.